|

|

- I'm Online Chat Now

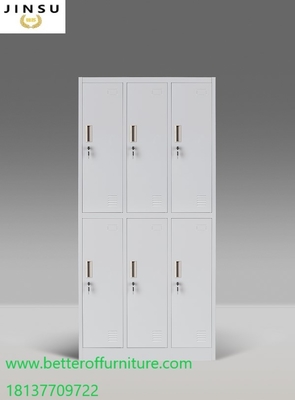

Six door steel locker storage cabinet gray color H1850XW900XD450MM Wardrobe Cabinet

Product Details:

Payment & Shipping Terms:

|

| Material: | SPCC | Height: | 1850mm |

|---|---|---|---|

| Width: | 900mm | Depth: | 450mm |

| Package: | Carton | Volume: | 0.17CBM |

Six door steel locker storage cabinet gray color H1850XW900XD450MM Wardrobe Cabinet

We LUOYANG JINSU OFFICE FURNITURE CO.,LTD can offer These full height/half height 6 door privacy lockers provide enough space for packages and lunch boxes as well as other medium sized items. Each of these small personnel lockers can also store up to six folded uniforms. Employees can quickly secure their belongings by securing the steel pull handle with a padlock. It can let the employee protect their private goods. The internal structure empty for the storage the clothes or other goods.The door surface will treatment by powder coating. We will made the vent hole to make sure the air good ventilation. The lock can use padlock or digital code lock.Also it can offer clothes rod to put the clothes in the cabinet.

We had offer the steel cabinet to USA,Canada,Spain,Austraila,Asia aera and so on.

For the six door specification as following :

| Locker Name | steel locker ,Iron locker ,Clothes-exchanged cabinet , Steel locker cabinet ,metal locker |

| Dimension |

H1850XW900XD450 mm ( H72.83X35.43X17.71 Inch size) Height:1850mm (72.83 inch size) Width:900mm (W35.43 inch size) Depth:450mm (D 17.71 inch size) Remark:if you need other dimension, Please tell us your requirement,our engineer will design for you. |

| Material | Regular height: 0.6mm,Cold rolled steel plate (0.5-1.2mm is available ) |

| specfication | 1.Handle,2.fixed shelf,3.hanger,4.vent hole,5.name tag 6.mirror |

| Handle structure | changable professional recessed handle,or any RAL color is avaiable |

| Door number | 6pcs |

| Steel Locker color | White, orange,Beige,charcoal, or any RAL color is available |

| Lock style | Cam lock,pad lock,code lock,electronic lock is available. |

| Surface treatment | Electrostaic powder coaring epoxy resin finish,NO smell and no harm to people health and environment. |

| Delivery time: | in stock,If ex-stock,It will need 30 days after getting the order |

| Structure | Knocked down or flat packing or your required |

| Package |

1).the locker cabinet are knocked down 2).5 ply standard export with polyfoam inner lining 3).PE foam between piece and piece,paper corner protections 4).All the assecories of 1 unit will be package in one individualy plastic bag 5).one piece package in one carton,seal with tape and packling belts. |

| Volume and MOQ | 0.14 m³,20 GP, Sample is available |

| Application | Office,school,home,hotel,hospital,company,factory, and other commercial area, stuff room, changing room, gym, government etc |

The 6 door steel locker actual picture as following:

![]()

![]()

![]()

The package as following :

![]()

The office furniture manufacture process as following:

1. Cutting: According to the design-drawings, the steel sheets(open and flat) are cut into different sizes by the high-accurated machines, without errors or burrs.

2. Pressing: The CNC machine tools and other machine tools work with the big-scale mould together to reach the required standard and cooperate with the flow line production, which assure the production efficiency and quality

3. Bending: Skilled workers and advanced facilities make sure the clear lines and perfect appearance

4. Welding: Locate the work pieces into the corresponding mould, firmly weld with CO2 shielded welding or argon-arc welding and including the laser welding then conduct slag removing and polishing.To insure all the edge must be flat without burrs,we will need to ask the worker to grind the corner.

5. Powder Coating process: All the sheet material parts will go through 13 treatments of water cleaning, acid-washing, phosphating etc. The imported automatic spray facilities and top-quality powder promise the coating to be flat and smooth, non-toxic and no smell.

All the process will need to pre-check by the worker, and then the Professional inspector will check again, the next steop will checking by team leader.

6. Installation: To ensure the firmness of every screw, the installation workshop adopts pneumatic tools to conduct mass and flowline production

7. Assembly and packing: Strict and special testing before packing and storage to make sure the products are highly-qualified.

Quality Control:

1) Every product quality will be checked & cleaned before packing

2) We will try our best to help clients when problems occurred,We can free offer the parts to customer if the problem will caused by ourself

3) Every step of production is carefully inspected by our professional QC clerk to ensure the quality of our products

Contact Person: Jean Yang

Tel: 18137709722

-

Nine Doors Steel Locker Staff Storage Clothes Cabinet H1850XW900XD450 Mm White Color

-

12 door steel locker H1850XW900XD450mm for School/Gym/Sports/Employee metal cabinet

-

15 door steel locker H1850XW900XD450mm for School/Gym/Sports/Employee metal cabinet

-

Partition steel cabinet 4/6/9/12 door for public space white and gray color available

-

Staff 3 Door Steel Locker H1850XW900XD400mm Metal Furniture Wardrobe Storage Cabinet

-

Office Furniture School Locker/ Gym Locker/Staff Locker/Steel Locker/Metal Locker